We Build, Program & Install Municipal Control Panels

MurCal Municipal has been automating engine and electric motor driven pumps for 60 years. Our municipal division was founded on the principle of developing efficient solutions to many of the control issues facing modernized water and sewage pumping stations, including flood control, sewage lift, well pumping and water booster applications. We build rugged, industry proven, SCADA system compatible control panels from the ground up to meet the specific requirements of the project.

Automation: All-Around Simplicity

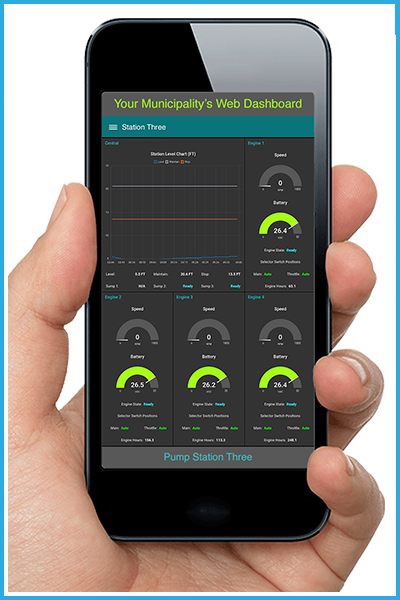

MurCal believes in “efficiency through technology”, using automation and remote monitoring. Automation is the use of various control systems for operating stationary internal combustion engines with minimal or reduced human intervention. Automation saves labor and allows for more efficient use of your equipment investment, by saving energy and materials while improving accuracy and precision. The ability to monitor and adjust operating parameters at your facility from a remote location is rapidly gaining favor with operators, allowing for increased productivity while reducing costly downtime.

The introduction of the Series 800 controller marks a renewed dedication to our customers. The Series 800 is an all-purpose engine controller, designed to meet the needs of nearly every municipality. The controller is designed to be a municipal-specific control platform, and incorporates the necessary hardware to efficiently execute these projects.

Series 800 Control Panel

The Series 800 Controller

The Series 800 control platform embodies the culmination of the experience we have gained over nearly 60 years in the control business. We enhanced the standard features, lowered the cost, increased the connectivity options, and increased the configurability by basing the controller on Linux, an open-source operating system.

The Series 800 benefits from a simplified modular design. We've reduced installation and maintenance costs, while greatly increasing the quality and reliability of the product. The Series 800's single board design eliminates the majority of inter-panel wiring that is traditionally seen with PLC control panels, while retaining features such as true hardware interlocks for local and remote E-Stops.

The Series 800 has the ability to withstand a wide ambient temperature range, comes standard in a NEMA 4X rated enclosure and has an HMI display that is viewable in extreme environments.

Series 800 Benefits

• Suitable for Booster, Well, and Flood Control Applications

• Large 7” touch HMI with Rich, Full-Color Graphics

• Single-Board Design Simplifies Maintenance

• Wi-Fi or Cellular Modem Capable

• Manual & Auto-Start Capable with Throttling Options

• Status and State of each controller indicated both locally and via MODBUS communication to central SCADA system.

• Installation, Service and Training available from MurCal.

Pump Control Features

Booster Pump Control Features

• Auto Start and Speed Control based on local system pressure.

• Remote control/monitoring via SCADA systems using MODBUS RTU communications.

• Special software routines to control Pre-Lube and Pump Control Valves.

• Pre-Lube Valve and engine control with adjustable delay and fault sensing.

• Pump Control Valve control on start and stop where required to control pressure surge.

• Speed Control for Warm-up, Minimum RPM, Maximum RPM, Engine and VFD drives.

• PID Speed Control to maintain discharge pressure as required by the application where VFD and Engine Drives are used.

• Fault annunciation both locally and via MODBUS communication to central SCADA system.

• Status and State of the controller indicated both locally and remotely to SCADA system.

Single Well Pump Control Features

• Auto Start and Speed control based on local system pressure.

• Speed control based on local pressure and/or discharge flow.

• Remote control/monitoring via SCADA systems using MODBUS RTU communications.

• Special software routines to control Pre-Lube, Pump Control Valves, Waste/Discharge Valves.

• Well Pre-Lube Valve control with adjustable delay and fault sensing.

• Engine Pre-Lube, Warm-Up, Cooldown, Post-Lube.

• Speed control for Warm-Up, Minimum RPM, Pump-To-Waste RPM, Maximum RPM, engine and VFD drives.

• Pump Control Valve control on start and stop where required to control pressure surge.

• Pump to Waste control with valve fault sensing and automatic switch-over to mainline pumping.

• PID Speed control to maintain discharge pressure or flow as required by the application where VFD and Engine Drives are used.

• Fault annunciation both locally and via MODBUS communication to central SCADA system. Status and State of the controller indicated both locally and remotely to SCADA system.

Lift Pump (de-watering, flood control, sewage) Control Features

• Auto Start and Speed Control based on local wet well level.

• Remote control/monitoring via SCADA systems using MODBUS RTU communications.

• Special software routines to control Pre-Lube, Pump Control Valves.

• Pre-Lube Valve and engine control with adjustable delay and fault sensing.

• Pump Control Valve control on start and stop where required to control pressure surge.

• Speed control for Warm-Up, Minimum RPM, Maximum RPM, engine and VFD drives.

• PID Speed Control to flow-match varying flow into wet well by maintaining a preset level or constant speed operation as required by the application where VFD and Engine Drives are used.

• Fault annunciation both locally and via MODBUS communication to central SCADA system.

• Status and State of the controller indicated both locally and remotely to SCADA system.

Multi-Drive Station Central Controller

MurCal Municipal's central controllers incorporate an easy to use HMI touchscreen, giving operators a better visual representation of what is going on with their engines. Our signature red and stainless steel panels are synonymous with quality. We build central control and communication with SCADA systems for Booster, Flood Control and Sewage Lift applications. The multi-drive station central controller performs the following:

• Automatic pump substitution on failure with intelligent pump alternation.

• Automatic speed synchronization of pumps as multiple engine and/or VFD drives are added based on demand.

• Control Area Network (CAN) communications between engine controllers to provide instantaneous communication of start commands, speed commands and status between engine controllers and central controller.

• Emergency operation capability with individual engine controllers able to operate independently, if fault is sensed with the central control system.

• PID speed control for variable speed drives such as engines and motors with VFD drives.

• Central controller can act as a Remote Terminal Unit with direct SCADA connection or can communicate with a separate RTU as required by the application.

Most central controller designs employ a 15” high-resolution touchscreen interface which can be customized to meet your unique automation needs, including data logging, alarm management and remote communication.